Commercial Fabrication Facility & Logistics Center

At First Class Upholstery, our West Nyack facility is more than a factory—it’s the engine behind our most ambitious builds. From custom cabinetry to architectural woodwork, this hub powers large-scale commercial projects and precision-crafted components that integrate seamlessly with our upholstery and installation workflows.

Custom Commercial Cabinetry & Millwork Fabrication

Built for Function & Style

Structural Integrity Meets Design

Furniture Production & CNC Precision

Distribution Hub for Custom Furniture & Commercial Cabinetry

Ready for Large-Scale Projects

Advanced Machinery for Exact Results

See our Contract Upholstery Team in action

Specialized Skills Working Together for Your Vision

This unique working arrangement brings together specialized strengths.

We are focuses on top-quality custom cabinets and large-scale fabrication, while First Class MasterCraft brings master craftsmanship in:

• Custom furniture frames

• Beautiful wall panels

• Bespoke bed frames

• Expert upholstery

• Meticulous furniture refinishing

• Precise antique restoration

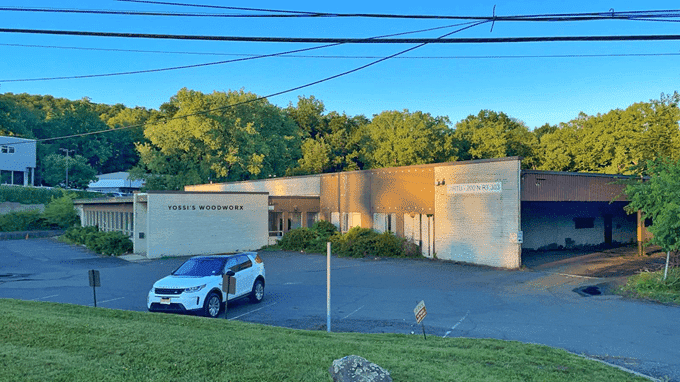

Projects crafted within Yossi’s Woodworx and by First Class MasterCraft reflect a fusion of precision and artistry. When they need our specialized skills, we’re there. When we need their advanced factory, they’re there—ensuring seamless, high-quality results for you.

How Our Coordinated Approach Benefits Your Project

• Comprehensive Solutions: Get all your custom furniture, upholstery, and woodworking needs met under one coordinated approach.

• Faster Project Completion: Streamlined workflows between our workshops and the factory reduce overall project times.

• Unmatched Quality: Combining specialized craftsmanship with precision machinery ensures top-tier results.

• Peace of Mind: Work with trusted experts who coordinate all stages of your complex project.

Precision CNC Machining & Integrated Upholstery Workflow

CNC Operator, uses advanced CNC machines for exact, repeatable cuts and complex designs.

• Hand-Tool Stations – Skilled artisans use traditional hand tools for fine details, legacy carving, and precise adjustments.

• Climate-Controlled Spray Bays – Special bays ensure perfect color matching and durable protective finishes for wood pieces.

• Integrated Staging – Dedicated areas prepare all components for upholstery transfer or direct installation.

Distribution Hub for Custom Furniture & Multi-Unit Production

Our large facility in West Nyack, NY (200 N Rte 303, West Nyack, NY 10994), acts as our main center for big projects and custom wood fabrication. It allows us to:

• Handle Commercial Scale – Take on very large projects like hotel and restaurant builds

• Ensure Precision – Use industrial machinery for exact, consistent custom woodworking

• Streamline Workflows – Our Fort Lee workshop and this factory work together smoothly, cutting down build and delivery time without sacrificing qualit

Warehouse & Product Manager, General Estimator

David plays a key role in the daily operations of our West Nyack facility. As Warehouse & Product Manager and General Estimator, he oversees everything from material flow and production timelines to final staging and delivery coordination. With years of hands-on experience in furniture logistics, custom fabrication, and client communication, Jesse ensures that every build—whether a single cabinet or a multi-piece commercial install—is executed with precision and care.

From custom headboards and millwork to large-scale hospitality fixtures, Jesse leads our fabrication and delivery teams with professionalism, logistical expertise, and a deep commitment to protecting your space and your investment. His understanding of both craftsmanship and operational flow helps transform raw materials into finished pieces that are ready to impress.

Easy Delivery & Installation from Our Hub

• Efficient Distribution Center – Our West Nyack facility serves as a central point for managing large-scale project logistics and distribution

• Flexible Scheduling – We offer on-site storage for components, allowing for flexible delivery times

• White Glove Service – Full White Glove Service from West Nyack to NYC, North Jersey, and Westchester for careful transport, assembly, and cleanup

• Expert Installation – Our crews follow detailed plans for perfect installation at your location

The Experts & Machines Behind the Scenes

Over 60 skilled professionals work at the factory, including cabinet makers, bench carpenters, our CNC Operator, and finishing experts. They deliver precision at every stage. We use advanced CNC routers, precision table saws, and climate-controlled spray bays to ensure every custom piece is perfect.

Meet Our Skilled Craftsmen

At First Class MasterCraft, our team is the backbone of every build. From upholstery and cabinetry to CNC precision and on-site repair, each specialist brings mastery, pride, and decades of experience. Led by Jeff and David, supported by experts like , Ed, Mark, Abraham, William, Chris, Nick, Carlos, Dean, Leon, Mike, John, Luis, and Jorge—we craft every piece with precision, unity, and First Class care.

Explore Our Connected Services

The Difference is in the Details

At First Class MasterCraft, our West Nyack facility isn’t just a production space—it’s where precision meets legacy. Every cut, carve, and finish is executed with care, whether we’re building a single heirloom frame or staging components for a multi-unit commercial install.

From CNC machining to hand-tool detailing, our team treats each piece with the same respect we give to the final product. We navigate complex builds, tight timelines, and high expectations with obsessive attention to detail—ensuring that what leaves our factory is flawless, functional, and ready to integrate seamlessly into your project.

It’s this level of craftsmanship that transforms a fabrication hub into a First Class experience.

Crafted with Legacy. Backed by Trust

Craftsmanship Since 1952

White Glove Service Available

Serving NYC & Tri-State Area

Fire-Rated & FAA-Compliant Materials

Crafted by Masters, Chosen by You

Each piece in our gallery reflects the precision, care, and artistry that define First Class MasterCraft. These aren’t just projects—they’re collaborations built on trust, detail, and timeless design. Whether you’re restoring a legacy or creating something new, your journey begins with a conversation. Let’s craft something extraordinary together.

Ready for a Large-Scale or Precision Project?

Let’s bring your vision to life with precision, scale, and seamless integration.

Or Reach Us Directly

Call: 201‑944‑2282

Email: info@firstclassmastercraft.com

Visit:

2431 Lemoine Ave, Fort Lee, NJ 07024

More Services That Support Our Distribution Hub

Our logistics and delivery systems are designed to support custom builds, restoration, and hospitality-grade installations. Explore more of what we offer:

White Glove Delivery – Secure transport for custom builds and restorations.

Workshop Location – Central hub for production and dispatch.

Commercial Intake – Start your routed delivery project.

Custom Furniture – Routed delivery for bespoke seating and builds.

Custom Cabinets – Coordinated logistics for cabinetry installations.

CNC Woodworking – Panel routing and delivery for precision-cut orders.